On September 22-24, the VI All Russia GMP Conference with international participation, organized by the Ministry of Industry and Trade of Russia together with the FSI “SID & GP”, was held in St. Petersburg. As usual, the Conference brought together leading international and Russian experts in the field of Good Manufacturing Practice (GMP). As part of the Conference, on September 23, a panel discussion and a round table for veterinary medicines manufacturers were organized by the FSBI “VGNKI” subordinated to Rosselkhoznadzor and the Association of Veterinary Pharmaceutical Manufacturers “AVFARM”.

Moderators of the panel discussion “Inspection of manufacturers of medicines for veterinary use. Regulation and statistics. The view of the state and business” were Vasilina Gritsyuk, Deputy Director of the FSBI “VGNKI” and Semen Zhavoronkov, Advisor to the Co-Chairman of the All-Russia Public Organization “Business Russia”.

In his speech, Danil Rudniaev, Deputy Director, Head of the Inspection Body of the FSBI “VGNKI”, spoke about how the inspection of sites for the manufacturing of veterinary medicines manufacturers for compliance with the GMP Rules requirements is organized during the period of restrictions related to the pandemic of a new coronavirus infection, including according to documents, using remote communication tools. He emphasized that the determination of the possibility of conducting remote inspections of each specific site is carried out on the basis of a risk analysis, the criteria of which were developed by specialists of the FSBI “VGNKI” on behalf of Rosselkhoznadzor [1].

The following criteria are taken into account:

- data on the results of previous Russian GMP inspections at the site;

- the degree of complexity of production (the greatest risk is the production of immunobiological medicines, then manufacture of sterile medicinal products, etc.);

- the effectiveness of the control system by the authorized bodies of the country where the site is located (statistical data based on the results of Russian inspections in this country);

- availability of analogues of the submitted medicinal products on the Russian market (scarce products during a pandemic or we can wait until an on-site inspection is carried out);

- availability of information on nonconformities in product quality (data from various sources).

Marie-Agnès Amos, Deputy Adviser for Agriculture, Assistant for Veterinary, Sanitary, Phytosanitary Issues for Russia, Kazakhstan, Belarus, Armenia, Uzbekistan, Kyrgyzstan of the Economic Service of the French Embassy in Russia spoke about the work of the French Agency for Veterinary Medicinal Products – ANMV.

Additional information on the structure and activities of the ANMV agency can be found here:

Erik De Ridder, Chair of the Regulatory Strategy Team, Member of the Leadership Team of the HealthforAnimals Association presented the topic “GMP inspection of (global) manufacturers of veterinary drugs: an industry perspective”. Summing up the results of his speech, on behalf of the association, he expressed the following:

– GMP is a mutual objective for both industry representatives and authorized bodies to ensure manufacturing meets consistently the approved quality standards;

– we welcome Good Manufacturing Practice;

– we welcome recent developments, such as the ability to submit a completed corrective and preventive action plan (CAPA plan) and the ability to conduct remote inspections;

– we welcome all initiatives towards more harmonization;

– we welcome all proposals leading to a better understanding of Russian inspectors and their expectations.

Sergey Yarunin, Director for Government Relations of the “AVPHARM” Association, presented statistics on the availability of GMP-certificates from foreign manufacturers that are members of the Association, broken down by types of medicines.

Alexander Velichko, Deputy Director of “VIC” Сompany for Government Relations, compared the conduct of GMP inspections by foreign and Russian inspectors [2].

In the afternoon, the round table “Topical issues of inspecting manufacturers of medicinal products for veterinary use for compliance with the GMP Rules requirements” was held.

The Q&A session was preceded by a speech of Oleg Yarosh, Head of the Department for Surveillance of Medicinal Products for Veterinary Use Turnover of Rosselkhoznadzor [3].

Finishing his speech, he touched upon the topic of issuing conclusions on compliance with the GMP Rules requirements to Russian manufacturers of medicinal products.

In accordance with clause 18. of the Decree of the Government of the Russian Federation No. 1314 of December 03, 2015 “On determining the compliance of manufacturers of medicinal products with the GMP Rules requirements”, the organization and conduct of inspections of manufacturers are carried out by the authorized body within the framework of licensing control over the implementation of activities for the production of medicinal products [4].

According to the Federal Law dated May 04, 2011 No. 99-FZ “On licensing of certain types of activities”, licensing control is carried out, in particular, through scheduled inspections [5].

This means that the enterprise, having passed the license control, has the right to submit an application for obtaining a conclusion on compliance with the GMP Rules requirements. In this case, a desktop inspection is carried out, consisting in the analysis of the submitted materials and the Site Master File valid at the time of submission of the application.

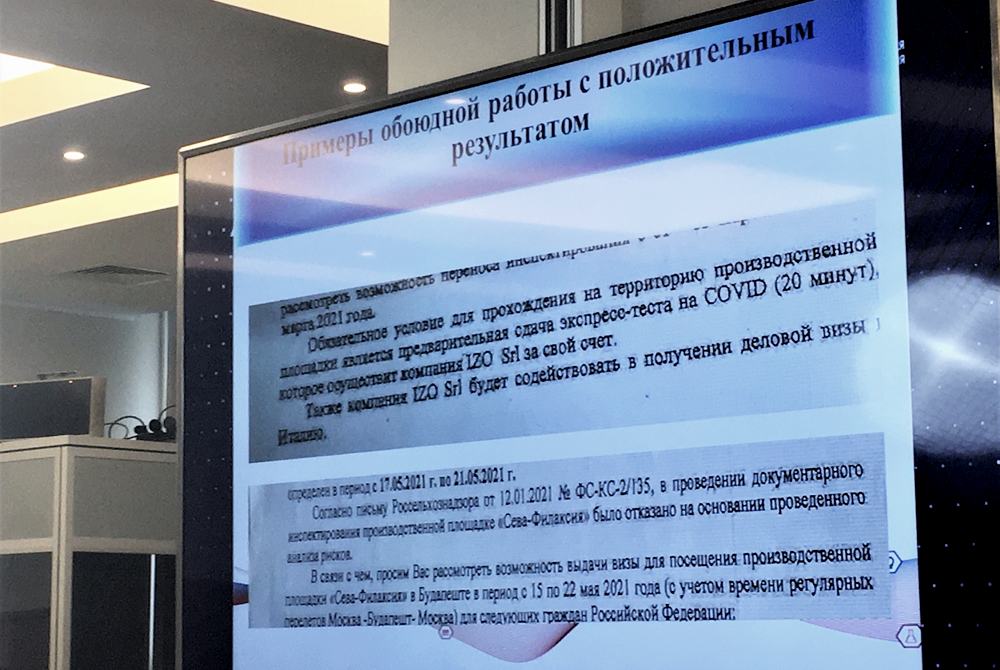

Before starting to answer questions, Danil Rudniaev once again asked representatives of foreign companies to solve organizational issues arising in the context of a pandemic by joint efforts (such as obtaining visas, assisting inspectors on the territory of the country where the manufacturing site is located, etc.). He gave examples of mutual work with a positive result and an example of the unwillingness of the representative office of a foreign company to work out the issue of organizing an inspection.

Then Danil Rudniaev and other experts answered questions from foreign and Russian manufacturers of medicinal products. Below are just some of the questions asked and the answers received.

Question 1:

Will retrospective validation executed by the manufacturer prior to the entry into force of the new Annex 15 to the EAEU GMP Rules “Qualification and Validation Requirements” be accepted during the inspection in 2022 [6]?

Answer: Yes, we will accept retrospective validation executed prior to the approval of this Annex, but within one year of its entry into force. The responsibility of the enterprise is to plan for the validation, but this is not an easy task: here you need to plan a budget, add the validation to a plan, draw up a timetable.

Question 2: The new Annex 15 introduces the requirements for the validation of packaging. What are your expectations regarding this process and is it possible here to use bracketing approach?

Answer: Here the principles remain the same: a minimum of three consecutive batches, and more is better. Bracketing is to some extent possible if there is a complete identity of the packaging: the same dimensions, the same carton boxes, labels, if variable information is applied in the same place and in the same way.

Question 3: Is it possible to combine the validation of packaging with the qualification of the packaging equipment, i.e. combine PQ and PV report?

Answer: GMP Rules provide such an opportunity, so you can combine them, but this should be clearly delineated by documents and stages.

Question 4: Is it acceptable to reduce the size of the second and third validation batches when validation of packaging, provided that the first batch used for validation was the maximum size (this batch was the same size as the intended commercial scale batch)?

Answer: No. Batches used for validation should be the same size as the intended commercial scale batches. We are also talking here about a “worst case” conditions, because the number of in-process controls when packaging such batches will be increased and the very functioning of the equipment over a long period of time is also significant.

Question 5: During validation of packaging, is it acceptable to test only different packaging types (in particular, blister packs with different numbers of tablets and blister packs of different sizes, rather than different strengths) if the critical parameters are identical for all strengths?

Answer: If we are talking about the number of blister packs packed in secondary packaging, then if these blister packs have the same number of cells and the same dimensions, variable information is applied in the same place and in the same way, carton boxes of the same size, then if at the same time in the blister pack tablets of the same size with different strengths will be packaged, then I do not see a problem here. Here we are interested in the packaging process, not the strength of the tablets in the blister cells.

Question 6: When changing a manufacturer/supplier of a substance, is it possible to perform process validation (for example, mixing) on only one batch?

Answer: The production technology of a substance may vary from manufacturer to manufacturer. As a result, we can get some specific parameters that we need, but we cannot accurately predict how the new substance will be compatible with other starting materials, how it can affect the stability of the medicinal product. When changing the manufacturer of a substance, validation should be performed on three batches. If we are talking about changing the supplier of a substance, then what you are asking about is acceptable.

Question 7: What is the best way to draw up copies of documents containing measures for the implementation of the CAPA plan, which a foreign manufacturer has the right to submit to an authorized institution, in accordance with clause 27. of the Decree of the Government of the Russian Federation No. 1314 of December 03, 2015 [4]? Will it be convenient for inspectors that, in addition to submitting printed copies of documents drawn up in the prescribed manner, the manufacturer also gives them access to these documents in the cloud storage? If filled personnel training sheets are submitted, which are executed according to the same template (and the variable information in them is, for example, the name of the procedure, signatures), will it be sufficient to attach only one version of the translation of this template?

Answer: We are moving together, and the review of CAPA is a new procedure. If we are talking about creating a cloud storage with temporary access, then this can be a plus, for example, to compare submitted copies of documents that cannot always be copied correctly. Yes, translation is a laborious process that takes a lot of time. If you are using the same training sheet template, then you can translate that template as an example. At the same time, I want to draw your attention to the fact that in the rest of the training sheets for the entire group of employees who are affected by the observation made, you need to translate all the information that changes: the topic of training, the name of the employee, the date of the training, etc. Proof of training for all employees is mandatory.

Question 8: Do you plan to create information platform for foreign manufacturers, where there is information on inspection?

Answer: There is the site of the FSBI “VGNKI”, there is the site of Rosselkhoznadzor, where the governing documents are published [7, 8]. The Rosselkhoznadzor website contains an application form for issuing a GMP conclusion [9]. We try to publish our guidelines. Everything already exists. The company itself can translate the required document into English.

Question 9: Do you plan to introduce remote inspections into permanent practice after the end of the pandemic?

Answer: No, definitely not.

Question 10: Do you accept a bracketing approach for consideration when performing a Media fill test, subject to a product quality risk analysis?

Answer: We have been discussing the issue of bracketing for a very long time. We accept it, and Recommendations on the application of the bracketing approach when performing the Media fill test were published on the Rosselkhoznadzor website almost a year and a half ago [10].

Question 11: Is it possible to monitor the stability of a medicinal product using the product of this the formulation only in the primary packaging (for example, in tightly sealed glass vials)?

Answer: If, at the same time, the medicine has a carton box, which is a secondary [marketed] package, then stability monitoring should be carried out in the secondary package.

Question 12: In 2020, documents on the validation of production processes were added to the list of documents required for submission to Rosselkhoznadzor in order to expand the list of medicinal products subject to the conclusion on compliance with the GMP Rules requirements [11]. For which processes should documents on the validation be submitted? Do we need to submit documentation for the manual packaging process?

Answer: If we are talking about the list of medicinal products that you want to expand, then, firstly, the added medicinal products should be of the same medicinal forms as the medicinal products that have already been submitted for inspection earlier. Secondly, they should be produced at the same facilities at which those medicinal products that have already been inspected are produced. You cannot add medicinal products that are produced on a line that the inspectors have not seen; or stored in a new warehouse that has been built. That is, for added medicines, production facilities, types of control should already be checked within the framework of the passed inspection. It is necessary to present for them the process validation, cleaning validation. If cleaning validation has been done using a “worst case” product approach, these added medicinal products should be considered in the risk analysis documents submitted to inspectors. If these have not been considered, then a risk analysis should be submitted to confirm that the “worst case” used in the cleaning validation also considers the added medicinal products. Otherwise, the submission of documents on a new validation is required. If we are talking about process validation using the Media fill test, then if the same production units, the same formats, and the same container-closure system are used that have already been inspected, then there is no need to submit additional documentation here. I would also like to point out that if the expansion of the list of medicinal products occurs some time after the inspection, then we would like to see a new report on the Media fill test. Manual packaging, like any other manual production, always requires more attention and additional control from the personnel. Therefore, here it is necessary to provide for a larger number of controls than with automated packaging.

The round table lasted more than two hours, and experts were able to answer many questions from manufacturers.

The material presented was prepared using data relevant to 10.10.2021. In case of new or additional data, the article can be updated.

_____________________________________________________________________________________

The Federal State Institution “State Institute of Drugs and Good Practices”, FSI “SID & GP” is an institution authorized to conduct inspections of manufacturers of medicinal products for human use manufactured outside the Russian Federation for compliance with the GMP rules requirements

The Federal State Budgetary Institution “The All-Russian State Center for Quality and Standardization of Veterinary Drugs and Feed”, FSBI “VGNKI” is an institution authorized to conduct inspections of manufacturers of veterinary medicinal products manufactured outside the Russian Federation for compliance with the GMP rules requirements

The Association of Veterinary Pharmaceutical Manufacturers, “AVFARM” is an association representing the interests of leading international pharmaceutical companies in the Russian Federation – manufacturers of modern, effective, safe and high-quality medicines for animals

Agence Nationale du Médicament Vétérinaire, ANMV is the French Agency for Veterinary Medicinal Products, which monitors the quality of medicinal products for veterinary use distributed in France. In addition, ANMV issues marketing authorizations for the veterinary medicinal products, the licensing of pharmaceutical sites for the manufacturing, distribution and export

HealthforAnimals is a non-profit, non-governmental organization representing companies and industry associations from developed and developing countries (manufacturers of veterinary pharmaceuticals, vaccines and other animal health products throughout the world, as well as the associations that represent companies at national and regional levels)

СREFERENCES:

- ФГБУ «ВГНКИ» / Пресс-центр / Новости / Эксперты ФГБУ «ВГНКИ» приняли участие в VI Всероссийской GMP-конференции. URL: http://www.vgnki.ru/eksperty-fgbu-vgnki-prinyali-uchastie-v-vi-vserossijskoj-gmp-konferencii.html (дата обращения 10.2021)

- Союз предприятий зообизнеса / Новости / Инспектирование производителей ветеринарных препаратов обсудили на Всероссийской GMP-конференции. URL: http://www.spzoo.ru/cntnt/default/n7045.html (дата обращения 10.10.2021)

- Союз предприятий зообизнеса / Новости / Круглый стол «Актуальные вопросы инспектирования». URL: http://www.spzoo.ru/cntnt/default/n7050.html (дата обращения 10.10.2021)

- ФГБУ «ВГНКИ» / Структура / Отдел инспекции производства на соответствие требованиям надлежащей производственной практики / Нормативно-правовая документация / Постановление Правительства РФ от 03.12.2015 N 1314 (ред. от 05.09.2020) «Об определении соответствия производителей лекарственных средств требованиям правил надлежащей производственной практики» (вместе с «Правилами организации и проведения инспектирования производителей лекарственных средств на соответствие требованиям правил надлежащей производственной практики, а также выдачи заключений о соответствии производителя лекарственных средств указанным требованиям»). URL: http://www.vgnki.ru/assets/files/post-1314.pdf (дата обращения 10.10.2021)

- ФГБУ «ВГНКИ» / Структура / Отдел инспекции производства на соответствие требованиям надлежащей производственной практики / Нормативно-правовая документация / Федеральный закон от 04.05.2011 N 99-ФЗ (ред. от 31.07.2020) «О лицензировании отдельных видов деятельности» (с изм. и доп., вступ. в силу с 28.03.2020). URL: http://www.vgnki.ru/assets/files/federalnyj-zakon-ot-04_05_2011-n-99-fz-red_-ot-31_07_2020.pdf (дата обращения 10.10.2021)

- Евразийский экономический союз / Распоряжение Коллегии Евразийской экономической комиссии от 19.05.2021 г. № 77 «О проекте Решения Совета Евразийской экономической комиссии «О внесении изменений в Правила надлежащей производственной практики Евразийского экономического союза». URL: https://docs.eaeunion.org/docs/ru-ru/01429302/err_24052021_77 (дата обращения 10.10.2021)

- Россельхознадзор / Регистрация и лицензирование / Инспектирование. Выдача заключения. URL: https://fsvps.gov.ru/fsvps/regLicensing/conclusion/index.html (дата обращения 10.10.2021)

- ФГБУ «ВГНКИ» / Структура / Отдел инспекции производства на соответствие требованиям надлежащей производственной практики. URL: http://www.vgnki.ru/otdel-inspekcii-proizvodstva-na-sootvetstvie-trebovaniyam-nadlezhashhej-proizvodstvennoj-praktiki.html (дата обращения 10.10.2021)

- Россельхознадзор / Регистрация и лицензирование / Инспектирование. Выдача заключения / Образцы документов / Форма заявления о выдаче заключения о соответствии производителя лекарственных средств для ветеринарного применения требованиям правил надлежащей производственной практики. URL: https://fsvps.gov.ru/fsvps-docs/ru/regLicensing/docs/regSamplepdf (дата обращения 10.10.2021)

- Россельхознадзор / Регистрация и лицензирование / Инспектирование. Выдача заключения / Для заявителя / Рекомендации по применению подхода крайних вариантов при валидации процессов производства. URL: https://fsvps.gov.ru/fsvps-docs/ru/regLicensing/docs/recommendations_validationpdf (дата обращения 10.10.2021)

- Россельхознадзор / Регистрация и лицензирование / Инспектирование. Выдача заключения / Для заявителя / Документы, необходимые для представления в Россельхознадзор с целью расширения списка лекарственных средств, на которые распространяется действие заключения о соответствии требованиям надлежащей производственной практики. URL: https://fsvps.gov.ru/fsvps-docs/ru/regLicensing/docs/conclusioDocspdf (дата обращения 10.10.2021)